overview

While researching farming & gardening methods I stumbled upon aquaponics - a blend of aquaculture and hydroponics and became enamored with its potential. It seemed to promise the ability to rid our dependency of pesticides, water and soil while increasing productivity and crop yield. If the method seems to promise everything shy of terraforming capabilities, where is the ubiquity?

what is aquaponics?

Aquaponics refers to any system that combines conventional aquaculture (raising aquatic animals such as snails, fish, crayfish or prawns in tanks) with hydroponics (cultivating plants in water) in a symbiotic environment. In normal aquaculture, excretions from the animals being raised can accumulate in the water, increasing toxicity. In an aquaponic system, water from an aquaculture system is fed to a hydroponic system where the by-products are broken down by nitrifying bacteria initially into nitrites and subsequently into nitrates that are utilized by the plants as nutrients. Then, the water is recirculated back to the aquaculture system.

Given the nature of a closed-loop ecosystem, creating an effecient, self-sustaining, commercially viable aquaponic farm is essentially a large optimization problem - where all subsystems must remain in balance in order to prevent ecosystem failure.

Apart from the system design and the variables associated, it is worth discussing the economic viability given climate change risk factors - such as an increase in disease, pest and extreme weather phenomena, general population growth (specifically in urban areas) and soil depletion rates - if commercial aquaponic systems are viable alternative to standard soil-based farming techniques.

system designs

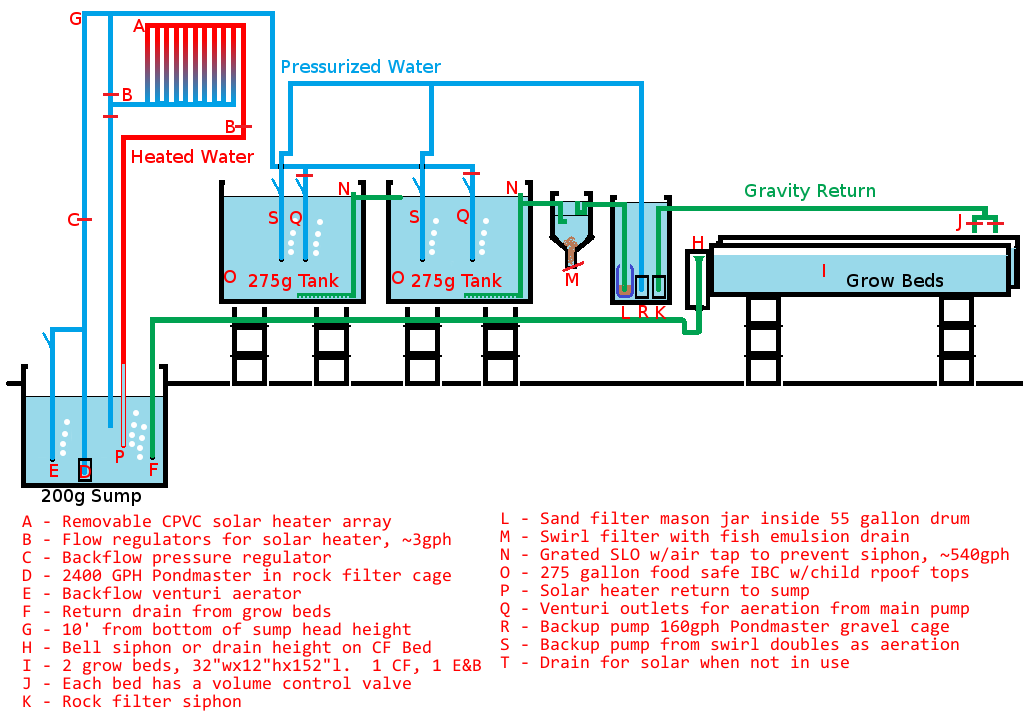

Standard “aquaponic system designs” resemble something like this aquaponicswork.com

Primary componets include:

- sump tank - primary collection and distribution point for all water

- water heater - to maintain water temp

- grow beds - self explanatory

- substrate type - soil replacement

- filters - swirl / small particulate

A “flood and drain” process is used to transfer nutrients and to the roots and provide sufficient ventilation for growth. There are many different substrate types that are optimum for specifc vegitation and flexibility of greenhouse design may be limited due to substrate mass. Aquaponic Food Production Systems, Simon Goddek et al

variables

Quick overview of the non-economic variables associated with an aquaponic design:

- light - how much is required for your vegetation? what light spectrum is optimum? how much direct sunlight can be used? How much needs to be supplemented with LEDs?

- water - nitrate, nitrite, pH, ammonia, pressure, temperature, etc.

- this needs to be balanced for both fish and plants. optimums may differ

- airflow

- bacterial relationships

- substrate type(s) - mass & greenhouse architecture, water

- germination

- fish - type for system, diets, water temp, etc.

- vegetation type

Additional economic variables:

- value of produce in geographic region

- yield / production rate

- transportation cost

- electricity costs (heat, light, airflow)

- water costs (minimal)

- labor (harvesting)

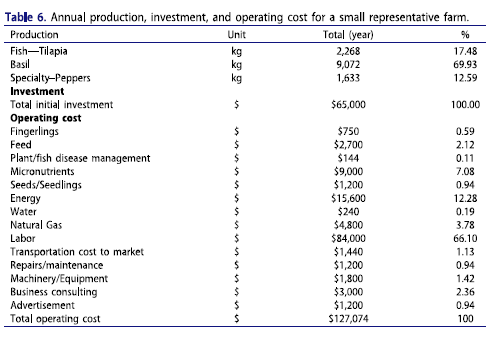

economic viability

There is not a lot of information on the ROI timelines of aquaponic systems. I assume becuase the technology required to commercially scale these systems has, until recently, remained cost prohibitive (e.g. LED lights). Additionally, many companies offering aquaponic based products also offer consulting services. Presumably, given the quantity of consultants relative to aquaponic farmers, it is more lucrative to consult than produce.

Recent reports suggest economic viability, while dependent on many factors such as geography and climate, is primarily dependent upon whether or not the farmer is able to offer (and charge for) organic products. Journal of Applied Agriculture

Further analysis show that labor, regardless of farm size, equates to 2/3 of total farm operational costs. If one was able to structure the greenhouse / farm is such a way where automated harvesting is a viable solution, aquaponic farming costs could begin to compete with non-organic produce.

Quagrainie et al 2018

Quagrainie et al 2018

market research and existing companies

Noteable companies in the space:

- Gotham greens - new york & chicago based local

- Aerofarms - new jersey based vertical farming company.

- Zipgrow (originally ‘Bright Agrotech’ this company was acquired by Plenty. Bright Agrotech’s founder, Nate Storey, now serves as Plenty’s CSO)

- Bowery – new York based vertical farming. one of the two major players in the vertical farming space.

- Plenty - san francisco based automated vertical farming company. recently received 200m investment from softbank capital.

similarities and differences

Similarities

- Primary product - leafy green variants

- Branding, message and competitive advantage - local, organic, growth 24/7, non-gmo, pesticide free, premium quality, etc.

- Expansion & M&A hisotry - limited; even companies such as Gotham Greens, who have been around since 2011, have limited expansion history

Differences

- Architecture - vertical, horizontal, stacked-horizontal

- System - aquaponics, hydroponics, aeroponics

- Harvest method - semi-automatic (plenty uses a robot arm to dismount the vertical towers prior to harvesting manually), manual (aerofarms uses large, hydraulic lifts to transport people up and down the aisles while harvesting)

Conclusion Agritech is an exciting space. The message is nobel - promising to better the planet’s inhabitants by increasing access to high quality healthy food at lower prices - and the ability to control virtually all variables associated with growing produce is attractive. But, while investment interest in urban farming apprears to have been increasing over the years, it is difficult to determine (1) if there is a successful, economically viable, commercial manufacturing model and (2) if general private interest in the technology is trending upward.

One of the most cited papers on the economics of small-scale commercial aquaponics estimates MIRR at ~7% (12-13% w/organic certification) listing the primary constraint being system maintenance and harvesting labor. Tokunaga et al 2015 With a more effecient system, margins could increase to compete with traditional agricultural methods.

design improvements

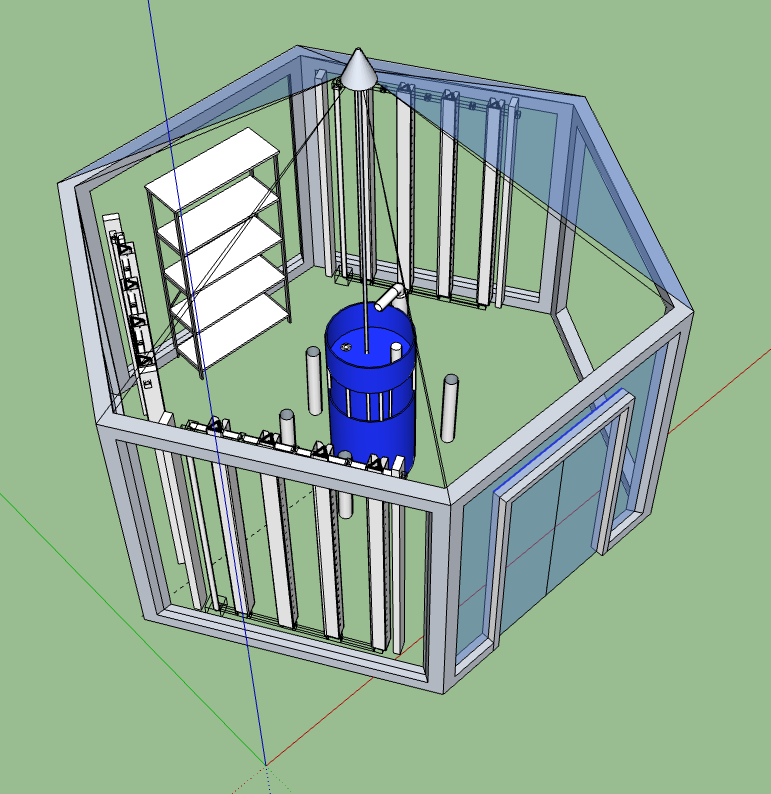

Based on the brief analysis above, a hybrid aeroponic / aquaponic, indoor, vertical greenhouse solution seems optimal to produce vertical growth vegitation (lettuce, tomatoes, herbs, etc.).

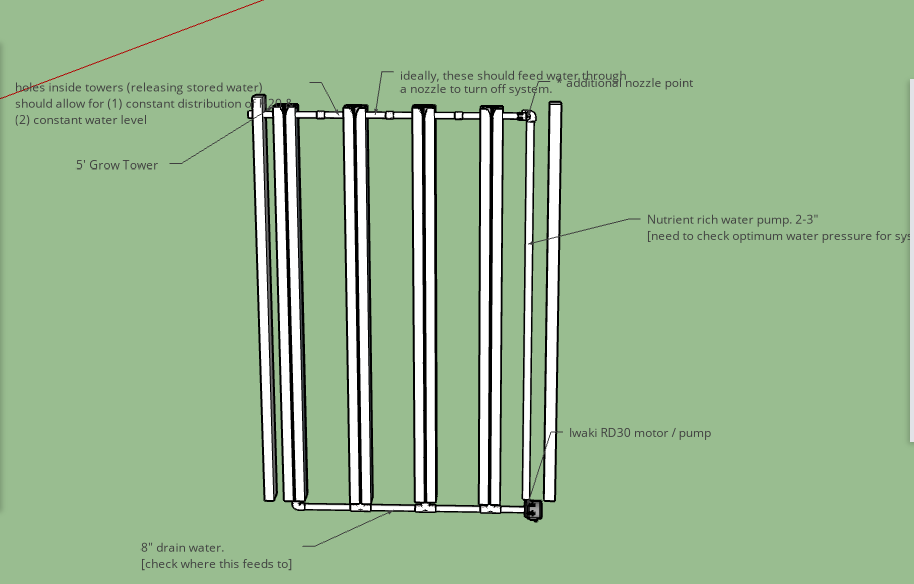

System components

- Plant & fish profiles - optimum living conditions and expected growth behaviors (with images) based on research compared to observation

- Airflow monitoring - system timers to turn fans on and off based on temp, biometric pressure, wind speed, etc.

- Automated fish feeding

- Temp control - water and air will be monitored and adjusted based on fish and plant profiles

- Light spectrum - red / blue light optimums based on plant profiles (yellow is not needed)

Architecture System is a closed-loop self sustaining system. Shelving units are dedicated to seedling germination and care. Even when factoring in labor, the quantity of seedlings per sq ft is not cost prohibitive. Image recognition based on plant profile will be used to determine when the system should harvest. Automated bucketing / harvesting method has not been completed. Center tank (sump, swirl, filter) is surrounded by sensors to ensure temperate climate. LED lights are not listed, but remain part of the vertical grow apparatus. Prototype is stored in an 7’ x 8’ x 9’ greenhouse.

Because other large players in the space have selected lettuce variants as their primary product, I will as well. I have selected Tilapia as the ideal fish based on their growth rate and my geography / climate.